Close

Blog Categories

Archives

Latest Posts

Is it possible to install a trackball keyboard vertically? A manufacturer of industrial robots turned to us to solve this problem. Here is the solution.

A manufacturer of industrial robots contacted us because they had purchased a trackball keyboard from their supplier. For reasons of both space and aesthetics, their keyboard had to be positioned vertically. However, when installed vertically, the pointing system did not work properly. Having received no response from their supplier, the customer turned to us to understand the problem and find a solution.

We carefully analysed our customer’s problem, and we realised that it was due to the choice of the pointing system: it was the mechanic trackball itself – typically found on industrial keyboards – to cause so many issues.

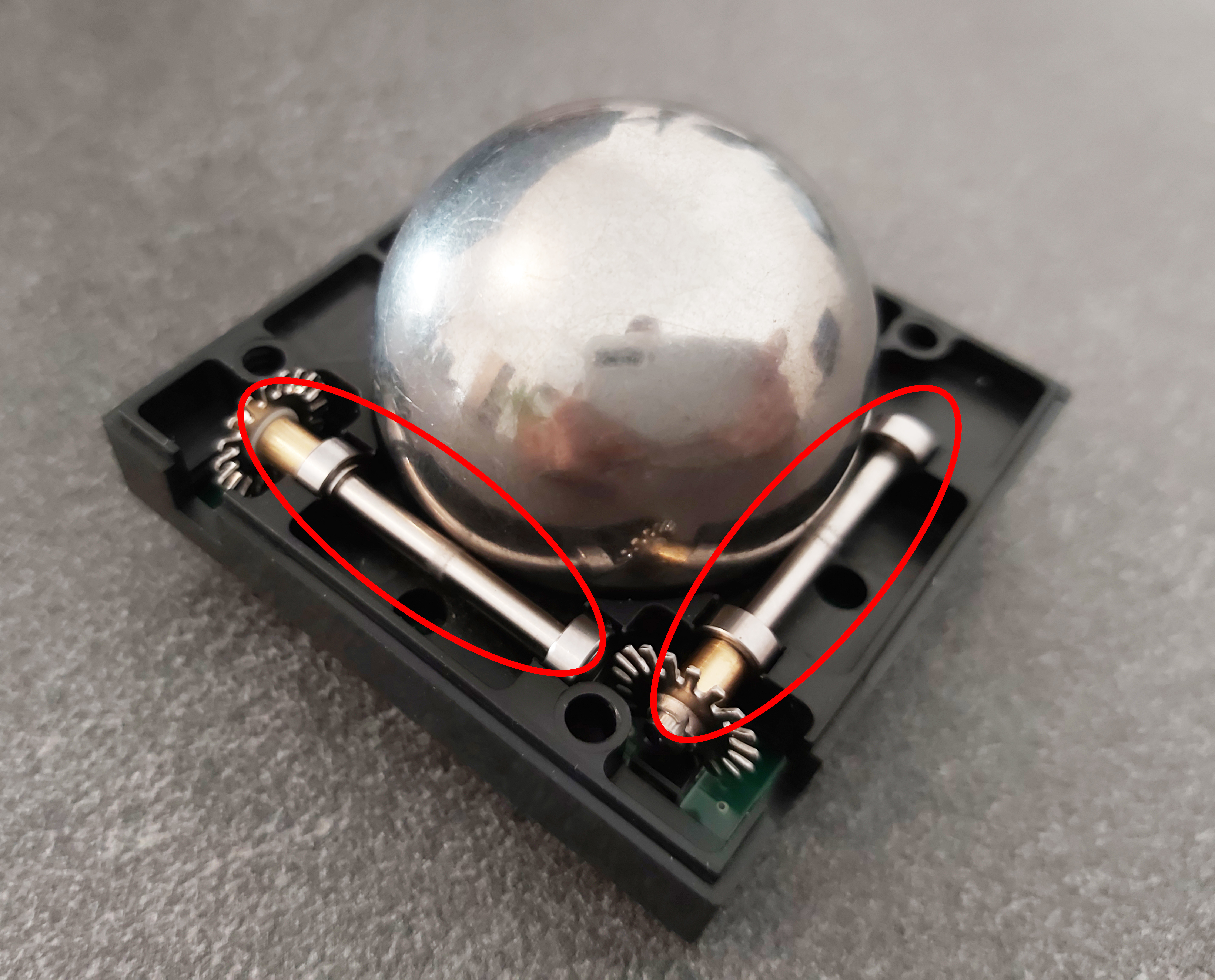

Let’s step back for a moment. The mechanical trackball is a kind of pointing device consisting mainly of a ball, free to rotate in a cavity where sensors detect its movement, rollers, and castors. When the trackball moves up and down, the ball drives the top roller moving the cursor on the screen in that direction. The same principle applies to left-right movements, which drive the roller positioned to the side of the ball.

When the keyboard is placed vertically, however, gravity comes into play. Indeed, it causes the ball to lose contact with the top roller, with the result that vertical pointing in the screen is no longer accurate. Thus, using a keyboard with a mechanical trackball for a vertical installation would not be a correct application for this kind of pointing system.

At this point, two options are available: use a touchpad or opt for another type of trackball. Our customer necessarily needed a trackball pointing system, as the user who had to interface with the product daily used thick gloves, for which the touchpad is not suitable.

Therefore, we suggested the use of the optical trackball. This particular pointing system does not work with a roller mechanism – like its mechanical counterpart – but with a laser, perceiving the ball movement in all directions even when installed vertically. In this way, the problem of vertical application of the keyboard is completely solved, guaranteeing full functionality of the pointing system, attractive design, and saving space in the application context.

Below is our TA007 keyboard with optical trackball in action integrated into our customer's production setting.

To find out more about this keyboard, click on this link -> TA007

***********************************************************

Are you developing a project, and you need a keyboard with optical pointing technology? Not sure which keyboard is best suited to your needs? Turn to industrial keyboards experts.

We will carefully analyse your project and advise you on the perfect product for your needs.

***********************************************************

Comments (0)

No comment